Heart of Steel

dC GEAR MOTORS

Product Catalog

Product Introduction & Customization

“Precise power, efficient transmission – our DC motors inject lasting vitality and stable performance into your equipment!”

BRUSH DC gear motor(Right angle )

Brushed DC motors are widely used in various types of equipment due to their simple structure, low cost, and easy control. They have large starting torque and fast response speed, making them suitable for frequent start-stop situations.

In addition, brushed motors have a wide speed regulation range, and precise speed control can be achieved by adjusting the voltage. They are also relatively easy to maintain, and the service life can be extended by replacing the carbon brushes. Despite the problem of carbon brush wear, they are still an economical and practical choice in many applications.

- Support customization

- Samples shipped separately

- After-sales technical support

BRUSHLESS DC GEAR MOTOR

Brushless DC motors have become the leader in modern motor technology due to their high efficiency, long life and low maintenance requirements.

They abandon traditional carbon brushes and commutators and use electronic commutation, which reduces mechanical wear and significantly improves reliability and durability. Brushless motors run smoothly and have low noise, making them suitable for high-precision control scenarios. Their high-efficiency conversion characteristics also mean lower energy consumption and better thermal management, making them an ideal choice for energy-saving and environmentally friendly applications.

- Support customization

- Samples shipped separately

- After-sales technical support

More customized solutions

We know that every customer’s needs are unique, so we provide motor customization services to ensure that you get the solution that best meets your application needs. Whether it is a specific power, size, speed or torque requirement, we can tailor it for you to ensure that the motor is perfectly matched with your system and improve overall performance and efficiency.

In addition, our customization services can optimize the design, remove unnecessary features, help you reduce costs, and meet special environmental or working conditions such as high temperature, high humidity or explosion-proof. Choosing our custom motors, you will get higher reliability and longer service life, reduce maintenance and replacement frequency, and save long-term operating costs. We are committed to providing you with the best quality products and services to help your business succeed.

- Support customization

- Samples shipped separately

- After-sales technical support

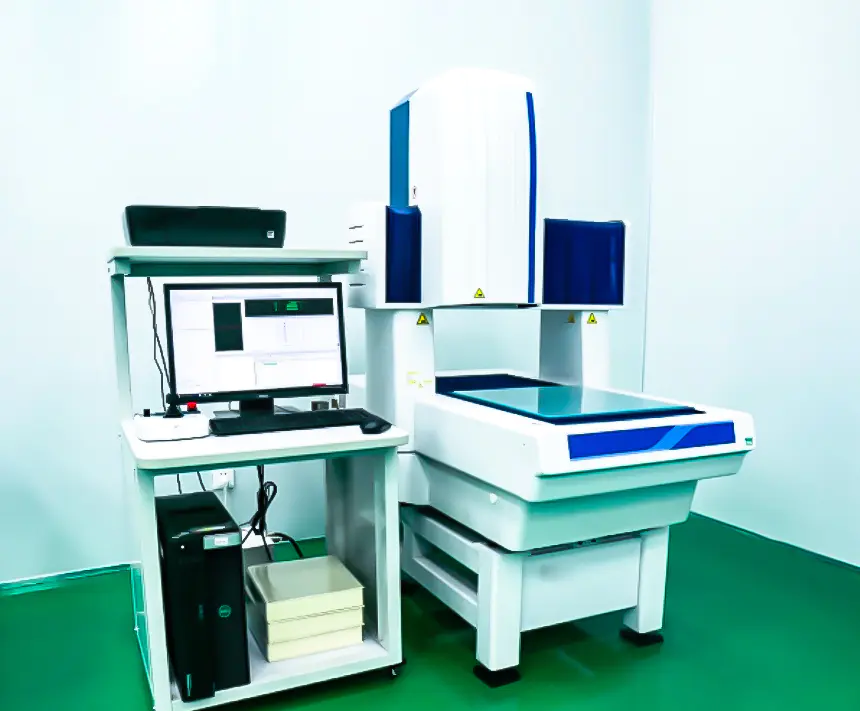

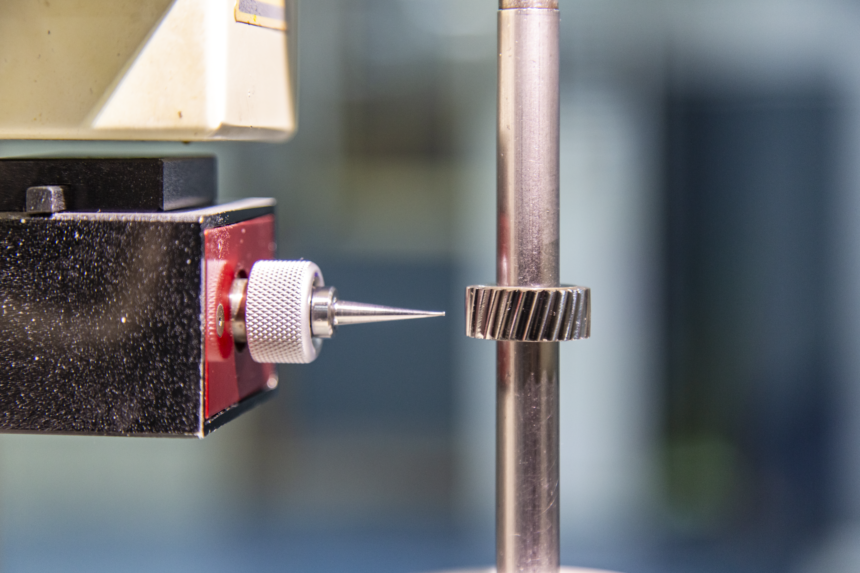

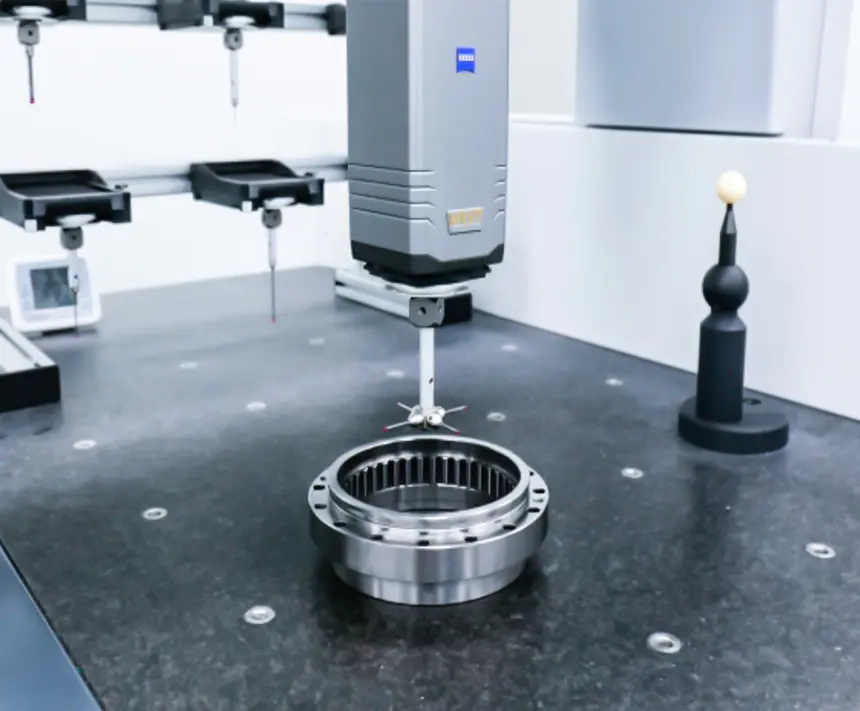

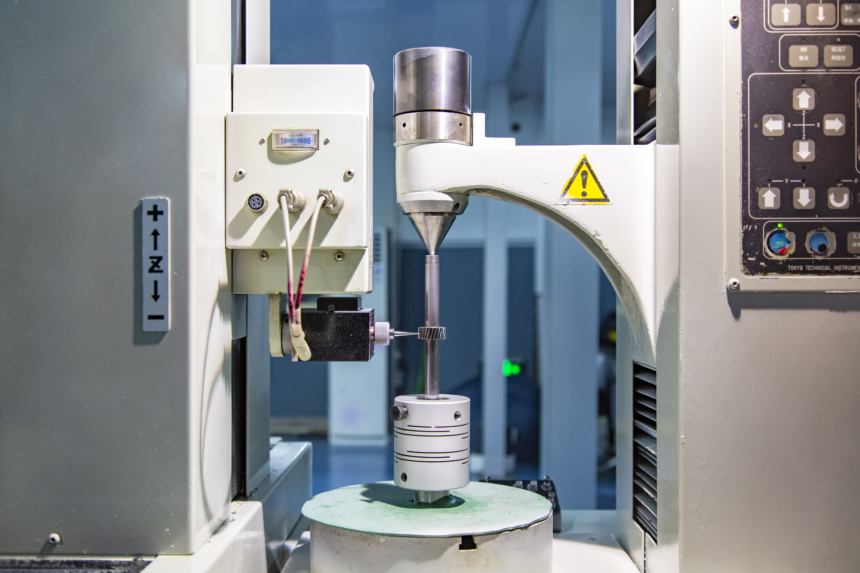

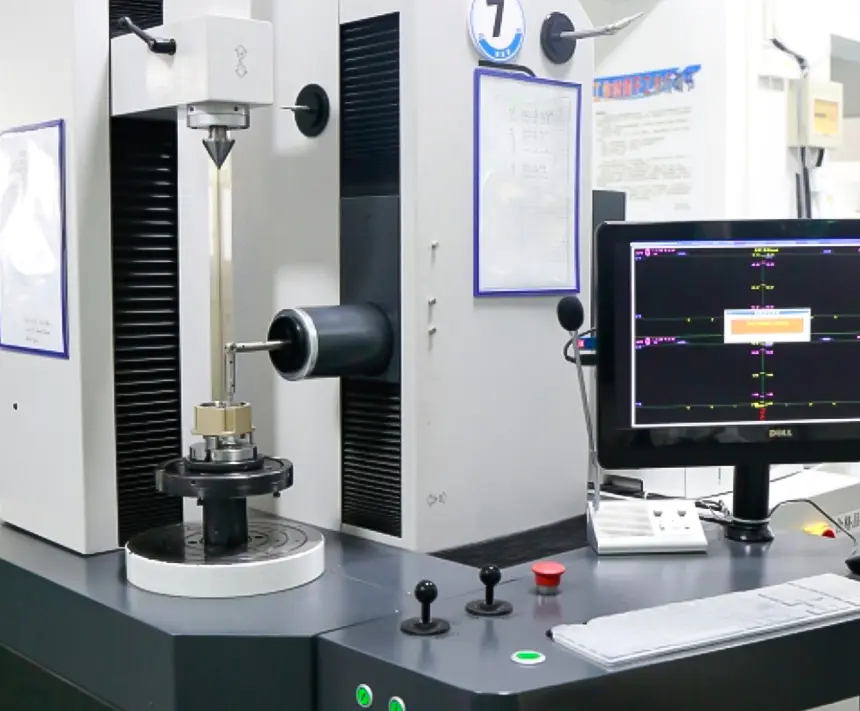

Our Factory

Sharp Tools Make Good Work

Application Areas

project list

Our advantages and applicable scenarios

“From industrial production lines to smart homes, our DC motors drive unlimited possibilities, empowering every wonderful moment!”

Transmission field

Application Areas

DC motors play a vital role in many fields due to their excellent performance and wide adaptability.

- Industrial Manufacturing

- Home appliances

- Transportation

- Medical Devices

- Robotic equipment

DC GEAR MOTORS

- Phone:+1 (859) 254-6589

- Email:[email protected]

why choose us

We have 20 years of experience in motor manufacturing, aiming to give machines life.

- Efficient and reliable performance

- Customized service

- Price concessions

- Environmental Compliance

- MOQ:1

- After-sales guarantee

- ...

faq

What is a motor?

An electric motor is a device that converts electrical energy into mechanical energy and is widely used in industrial, commercial and household equipment.

What are the main types of motors?

The main types include AC motors, DC motors, stepper motors, servo motors and brushless DC motors, etc.

What is the difference between AC motor and DC motor?

AC motors use AC power and are typically used in fixed speed applications; DC motors use DC power and are suitable for applications that require variable speed.

How to choose the right motor?

When selecting a motor, factors such as power, speed, torque, efficiency, size and cost need to be considered, as well as the specific needs of the application.

What does the energy efficiency rating of a motor mean?

The energy efficiency rating indicates the energy utilization efficiency of the motor. The higher the rating, the smaller the loss of the motor when converting electrical energy into mechanical energy.

What are the basic points of motor maintenance?

Regularly check the electrical connections of the motor, clean the motor housing, lubricate the bearings, check for worn parts and replace them in time.

What are the possible causes of motor overheating?

Possible causes include overload, poor ventilation, high ambient temperature, unstable voltage or internal fault.

How to calculate the power requirements of a motor?

It is calculated using the corresponding formula based on parameters such as load characteristics, operating time and required torque.

Can the motor be reversed?

Yes, reversing the rotation of a motor can be achieved by changing the polarity of the power supply (for DC motors) or by swapping two phases (for some AC motors).

What is a frequency converter and how does it work with a motor?

A frequency converter is an electronic device that adjusts the input frequency and voltage of an AC motor to control the speed and torque of the motor.

CLIENT SAY

Trusted worldwide for our experience

Hendrik Morella

Carryn Zenith

Danielle Soca

LETS TALK

let's keep in touch

GET IN TOUCH

Hello! If you are looking for efficient and reliable motor products, we provide you with a variety of models to meet different needs.

Feel free to contact our professional team for detailed consultation and customized solutions. We look forward to serving you!

call us

+173 - 2720 - 5120

website

www.epgearmotor.com